Pittsburgh was once as renowned for pollution as it was for industry and manufacturing. Decades after the Smoky City cleaned up its act and became a modern pillar of education, healthcare, technology, and finance, many people still associate Pittsburgh with a coal-gray haze.

Now manufacturing itself has undergone a millennial renaissance, yet it still carries a bad reputation as dirty and dangerous work.

But like Pittsburgh, the nature of industry has changed.

No longer a relic of the Industrial Revolution, modern skilled manufacturing runs on advanced technologies that require a solid foundation in STEM subjects and the ability to adapt quickly to evolving methodologies. The outdated stigma associated with manufacturing, the wave of senior engineers reaching retirement age, and the decline of shop classes in public schools have all contributed to a deficit of skilled workers prepared to take up the manufacturing mantle.

Now it falls to industry leaders to educate the next generation.

While public schools are slow to change and outsourcing continues to stretch homegrown talent thin, apprenticeship programs and vocational education can still bridge the gap.

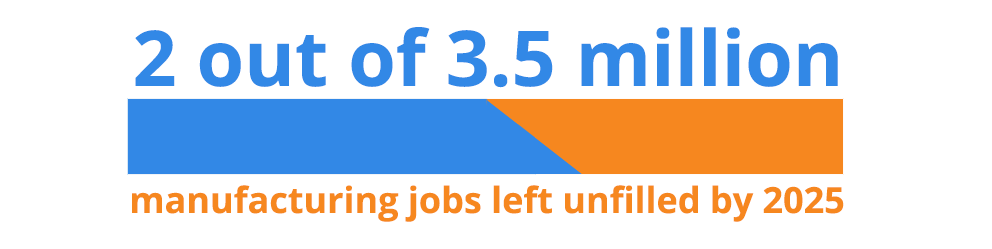

Educating workers is half the battle. According to research by Deloitte and the Manufacturing Institute, almost 3.5 million manufacturing jobs will be open by 2025, and 2 million of those will go unfilled due to the lack of skilled workers.

For potential students, it’s a huge opportunity to launch dynamic careers with a high rate of employment. Industry leaders just have to meet them halfway.

Premier Automation closes the gap by partnering with local vocational schools like Triangle Tech.

Getting involved with schools and community colleges encourages students to consider an industrial career by providing a clear path to employment.

According to the Deloitte and Manufacturing Institute research, industry executives cited the following strategies as the most effective for gaining skilled manufacturing workers:

As a partner with local vocational school Triangle Tech, Premier Automation interviews every graduating class to gain skilled entry-level applicants, while students transition directly from the classroom to the workforce where they receive specialized internal training. Triangle Tech graduates go on to become some of Premier Automation's group leaders, test technicians, and engineers.

Triangle Tech prepares students for the modern demands of industry by providing hands-on training labs and a diverse curriculum, including classes like Cost Estimation and Technical Writing in addition to a STEM-based core curriculum. Premier Automation builds on that foundation with decades of expertise in over 16 major industries.

Premier Automation also hosts informative tours for Electrical Engineering students from schools like Penn State, University of Pittsburgh, Virginia Tech, University of Dayton, and Princeton.

About Premier Automation:

We are an automation solutions company that invests in our engineers to develop the best talent and offer the experience and skills to improve our customer's bottom line. Talk to one of our experienced engineers to learn more about what we can do for you.